Data ya Msingi

Aina ya Msingi:

1.Mtindo wa kondakta mmoja uliowekwa maboksi

2.Mtindo wa kondakta pacha

3.Mikono ya mwisho ya kamba isiyo na maboksi

Sifa

Jumla ya sehemu nzima: 0.25 ~ 150mm²

Uwekaji usimbaji rangi na vipimo vya bomba hadi DIN 46228, sehemu ya 4(0.5~50mm²)

Halide bure, Moto retardant unaweza kukubali

Inastahimili joto 105℃(PP) 120℃ (PA)

Nyenzo:

99% Copper safi

Synthetic: Polypropen(PP), Polyamide(PA)

Uso

Bati-plated kulinda dhidi ya kutu

Maelezo ya agizo

Sasa inapatikana pia katika masanduku ya plastiki kwa mahitaji madogo.Katika hali ya kawaida hatuna mahitaji ya MOQ kwa ufungashaji wa mifuko.

Data ya Kiufundi

Nyenzo ya Kuendesha (isipokuwa Masafa ya Kuunganisha Haraka)

| Shaba | 99.9% safi |

| Nguvu ya Mkazo | 200MPa |

| Ukadiriaji wa Ductile | 35% |

| Jimbo la Mwisho la Metal | Sehemu ya bidhaa iliyokatwa |

| Maudhui ya oksijeni | Upeo wa 50ppm |

|

|

|

| Shaba | 30% Zinki 70% Copper |

| Nguvu ya Mkazo | 580 Mpa |

| Ukadiriaji wa Ductile | 6%. |

| Jimbo la Mwisho la Metal | Sehemu ya bidhaa iliyokatwa |

|

|

|

| Nyenzo | Bati |

| Maudhui ya bati | 99.90% |

| Metali Nyingine | Kiongozi + Antimoni |

| Unene wa Kuweka | Mikroni 1.5 |

|

|

|

| Uendeshaji wa Jumla | IACS 98.5%. |

| Upinzani kamili | 1.738 micro-ohm cm |

|

|

|

| Nyenzo | PVC kwa wote isipokuwa nailoni 6 au nailoni 66 - kwa IQC |

| Voltage ya kuvunjika | 1.5 k V(dakika) |

| Upinzani wa insulation | Zaidi ya 100 meg ohms |

| Voltage ya kufanya kazi | Hadi 300V AC/DC |

|

|

|

| Kabla ya Insulate | -40 ℃ hadi +150 ℃ |

| Shaba | 145 ℃ |

| Bati iliyowekwa | 160 ℃ |

MAALUM

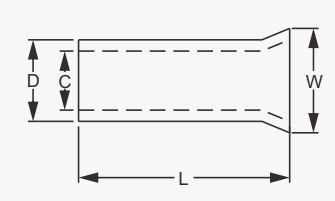

| Sehemu ya msalaba (mm²) | Kipengee Na. | Vipimo(mm) | AWG |

| Sehemu ya msalaba (mm²) | Kipengee Na. | Vipimo(mm) | AWG | ||||||

| L | W | D | C |

| L | W | D | C | ||||||

| 0.25 | EN0206 | 6 | 1.5 | 1.1 | 0.8 | #26 |

| 10 | EN10-18 | 18 | 5.8 | 4.9 | 4.5 | #8 |

| EN0208 | 8 |

| EN10-20 | 20 | ||||||||||

| 0.34 | EN0306 | 6 | #24 |

| EN10-25 | 25 | ||||||||

| EN0308 | 8 |

| 16 | EN16-12 | 12 | 7.2 | 6.2 | 5.8 | #6 | |||||

| 0.5 | EN0506 | 6 | 1.7 | 1.3 | `1.0 | #22 |

| EN16-16 | 16 | |||||

| EN0508 | 8 |

| EN16-18 | 18 | ||||||||||

| EN0510 | 10 |

| EN16-20 | 20 | ||||||||||

| EN0512 | 12 |

| EN16-22 | 22 | ||||||||||

| 0.75 | EN7506 | 6 | 1.9 | 1.5 | 1.2 | #20 |

| EN16-25 | 25 | |||||

| EN7508 | 8 |

| 25 | EN25-12 | 12 | 9.1 | 7.9 | 7.5 | #4 | |||||

| EN7510 | 10 |

| EN25-16 | 16 | ||||||||||

| EN7512 | 12 |

| EN25-18 | 18 | ||||||||||

| 1.0 | EN1006 | 6 | 2.2 | 1.7 | 1.4 | #18 |

| EN25-22 | 22 | |||||

| EN1008 | 8 |

| EN25-25 | 25 | ||||||||||

| EN1010 | 10 |

| 35 | EN35-16 | 16 | 10.2 | 8.7 | 8.3 | #2 | |||||

| EN1012 | 12 |

| EN35-20 | 20 | ||||||||||

| EN1018 | 18 |

| EN35-25 | 25 | ||||||||||

| 1.5 | EN1508 | 8 | 2.5 | 2.0 | 1.7 | #16 |

| 50 | EN50-12 | 12 | 12.7 | 10.9 | 10.3 | #1 |

| EN1510 | 10 |

| EN50-18 | 18 | ||||||||||

| EN1512 | 12 |

| EN50-22 | 22 | ||||||||||

| EN1518 | 18 |

| EN50-25 | 25 | ||||||||||

| 2.5 | EN2506 | 6 | 3.3 | 2.6 | 2.3 | #14 |

| 70 | EN70-22 | 22 | 15.8 | 14.3 | 13.5 | 2/0 |

| EN2508 | 8 |

| EN70-25 | 25 | ||||||||||

| EN2510 | 10 |

| EN70-32 | 32 | ||||||||||

| EN2512 | 12 |

| 95 | EN95-25 | 25 | 17.3 | 15.6 | 14.8 | 3/0 | |||||

| EN2518 | 18 |

| EN95-30 | 30 | ||||||||||

| 4 | EN4009 | 9 | 3.9 | 3.2 | 2.8 | #12 |

| EN95-34 | 34 | |||||

| EN4012 | 12 |

| 120 | EN120-30 | 30 | 20.2 | 17.7 | 16.7 | 4/0 | |||||

| EN4018 | 18 |

| EN120-34 | 34 | ||||||||||

| 6 | EN6010 | 10 | 4.7 | 3.9 | 3.5 | #10 |

| EN120-38 | 38 | |||||

| EN6012 | 12 |

| 150 | EN150-32 | 32 | 23 | 20.6 | 19.6 | 250/300 | |||||

| EN6018 | 18 |

| EN150-40 | 40 | ||||||||||

| 10 | EN10-12 | 12 | 5.8 | 4.9 | 4.5 | #8 |

| 185 | EN185-32 | 32 | 23.9 | 21.4 | 20.2 | 300/350 |

| EN10-16 | 16 |

| EN185-40 | 40 | ||||||||||